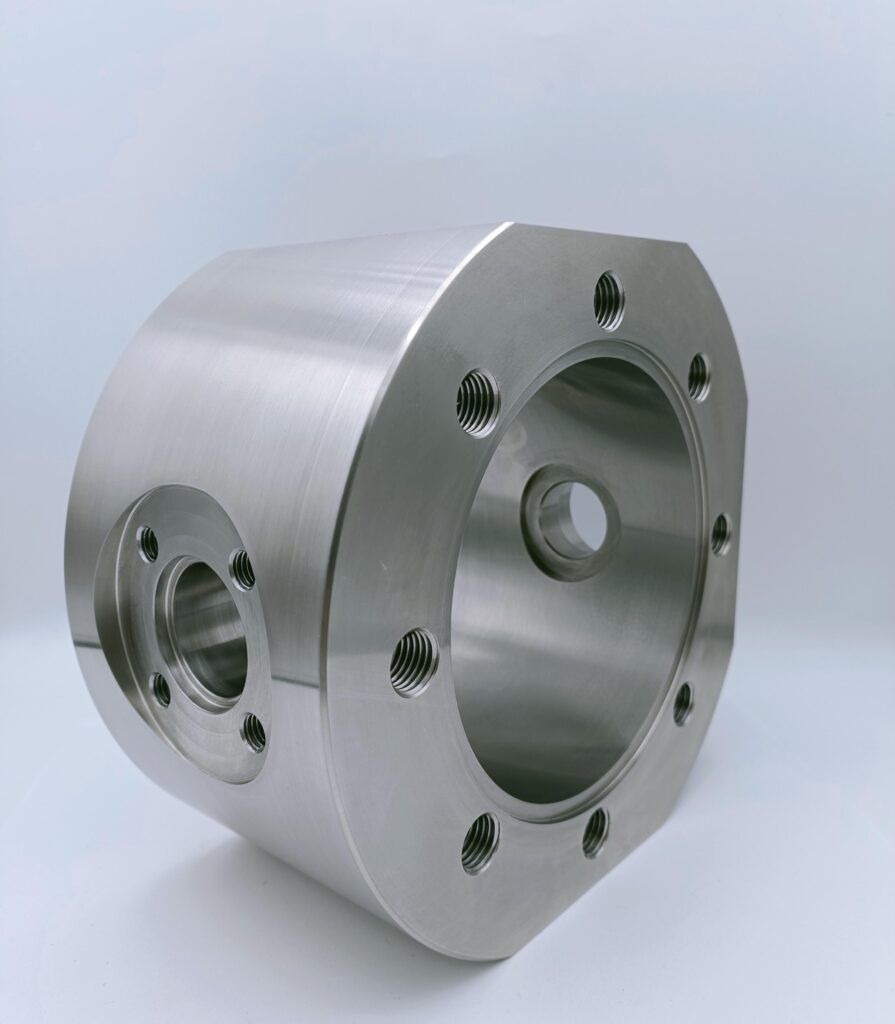

Nickel plated trunnion mounted ball valve

Most parts of this valve were machined from SS316L and were extremely strictly toleranced considering they will later be built into a European nuclear plant.

Multiple fits such as H6, g5, f6 and e8 on the various parts meant that we had to perform more in-line dimensional checks than usual.

The design of the ball also stood out. The nickel plating results in high surface hardness and consequently provides good wear resistance. The ball is supported in the valve body by means of a bronze bushing. Provecta also took care of the installation of the bearing bush and the final finishing.

Our specific knowledge of galvano plating proved to be an asset for this project

The material of the stem was: 1.4980, A-286, Grade 660. A heat-resistant steel with high strength, creep resistance, low magnetic permeability and high oxidation resistance. In addition to excellent properties at high temperatures (650- 700°C), it is also often used at cryogenic temperatures.

Typical applications of this base material can be found in the aerospace and energy sectors. E.g. heavy rotors, gas turbine blades, steam turbines, parts of pressure equipment, reactors and rockets.

Jaspar valves’ experience goes back decades, showing that they are an acknowledged and reliable supplier in the nuclear sector. Provecta has been a regular partner for several years and we wish to thank the team at Jaspar once again for their recurring trust in our services.